Despite using an air compressor for various projects, most people are confused about its regulator. There are many misconceptions about how this particular part functions and how to set up an air pressure regulator properly.

The purpose of the adjustment air compressor pressure regulator is to reduce the circulating air pressure to your downstream tool application.

What is Air Compressor Pressure Regulator?

An air compressor pressure regulator is a vital piece of equipment in any pneumatic system. It controls the amount of pressure that is delivered to the air tools, and helps to ensure that they are operating at peak efficiency.

Without a properly functioning air compressor regulator, your air compressor could be working overtime and using more energy than necessary.

Where it is located?

An air compressor pressure regulator is typically installed inline between the air compressor and the air tools. It consists of a gauge that measures the amount of pressure in the system, and a knob or lever that can be adjusted to increase or decrease the amount of pressure being delivered.

Misconceptions About Air Compressor Regulator Setup

There are a lot of misconceptions about air pressure regulators out there.

- Some people think that they are only necessary for very large compressors, while others believe that they should be avoided altogether. Neither of these beliefs is entirely accurate.

In reality, an air compressor pressure regulator can be a valuable addition to any pneumatic system – regardless of its size or power. - Another common misconception is that air pressure regulators are only needed for industrial-sized compressors. This simply isn’t true. While larger units may require more heavy-duty regulators, even small consumer-grade models can benefit from having one installed.

Pressure regulators help to ensure that your air tools are operating at peak efficiency, and can save you money in the long run by preventing your compressor from working overtime. - A lot of people think that pressure regulators cause more problems than they solve. This may have been true in the past, but modern regulator designs are much more reliable and user-friendly than their predecessors.

If you take proper care of your unit (including regular maintenance and cleaning), then it should give you years of trouble-free service.

For Example, If you are using a piece of equipment that needs 60 PSI to run correctly, a supply of 80 PSI will damage the machine as it can’t handle that much pressure.

Again, if you adjusted the actuator to such a low-pressure state that not even 60 PSI is supplied, the equipment won’t function properly. This is why the set range of PSI is so important to note before working on the pressure adjusting knob.

Types of air pressure regulators

There are two types of air compressor pressure regulators – analog and digital. Analog air compressor pressure regulators have a knob that you turn to adjust the pressure.

Digital air compressor pressure regulators have a digital display that shows you the current pressure, and allows you to set the desired Pressure with the push of a button.

Why use an air compressor pressure regulator?

Analog and digital Air Compressor Pressure Regulators serve different purposes depending on your needs. If you need to save money on your energy bill, or if you want more control over the amount of compressed air flowing through your system, then an analog regulator is right for you.

On the other hand, if precise control is essential in your application, or if monitoring multiple pressures is necessary, then a digital regulator should be used instead. In some cases both types may be used together in order to take advantage of each one’s strengths.

How do I adjust the pressure on my air compressor?

Here’s a step-by-step guide on how to do so:

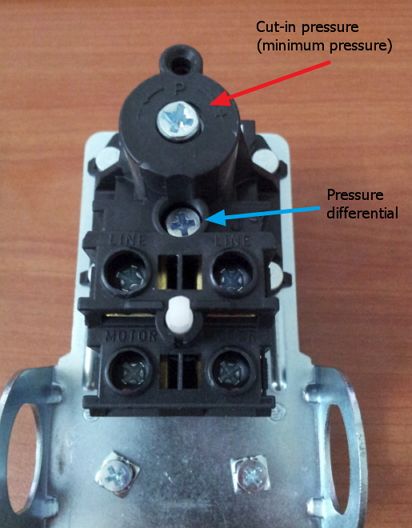

- Locate the pressure regulator knob or screw. This is typically located near the outlet port of the air compressor.

- Adjust the knob or screw until you reach the desired output pressure. Be careful not to over-tighten, as this could damage the regulator.

- Once you’ve adjusted the pressure regulator, check the gauge to make sure that it is reading correctly. If not, repeat steps 2 and 3 until it does.

That’s all there is to it! By following these simple steps, you can easily adjust the pressure regulator on your air compressor.

How do I adjust the pressure relief valve on my air compressor?

The pressure relief valve is a safety device that helps release excess pressure from the air compressor. If the pressure relief valve is not working properly, it could cause serious damage to the air compressor.

Here’s how to adjust the pressure relief valve on your air compressor:

- Locate the pressure relief valve on your air compressor. It should be located near the top of the unit.

- Use a wrench to loosen the nut that secures the cover over the pressure relief valve. Be careful not to over-tighten and strip the nut.

- Remove cover over pressure release value. You will see a spring -loaded plunger inside. This is what releases excess pressure when needed.

- Gently press down on the spring-loaded plunger until you hear a gentle hissing sound coming from inside the unit. As you release the spring, there should now be more resistance, indicating that compressed air is escaping through this valve.

- Replace the cover over pressure relief valve and tighten the securing nut. Again, be careful not to over-tighten.

- Test the air compressor by turn it on and letting it build up pressure. The pressure relief valve should release any excess pressure automatically.

FAQs – about Pressure switch control valve and air compressor

What should regulator pressure be at on an air compressor?

The regulator pressure on an air compressor should be set at around 90 psi.

Where is the unloader valve on air compressor?

The unloader valve is located on the side of the air compressor. It is a small, black valve that releases pressure from the air compressor when it is not in use.

Do you need a regulator on an air compressor?

A regulator is not required on an air compressor, but it can be helpful in regulating the pressure of the air coming out of the unit.

Can a pressure regulator increase pressure?

No, a pressure regulator can only reduce the pressure of air coming out of an air compressor.

Final talks

If your air compressor isn’t performing as well as it used to, or the pressure gauge isn’t reading accurately, adjusting the pressure regulator may help. Be sure to carefully follow the steps outlined above to avoid damaging the regulator.

Don’t forget to keep in mind the misconception regarding air compressor. Now enjoy your air compressor at its full potential!